What is multi location management? It’s a strategic approach to overseeing operations at various sites, ensuring that businesses operate smoothly and uniformly, no matter the number of locations. This introduction sets the stage for discussing the ins and outs, the systems in place, and the strategies deployed for successful multi location management, paving the way for the detailed insights that follow.

Whats in this article?

- Mastering Multi Site Operations: What is Multi Location Management and Why It Matters

- Understanding Multi Location Management

- The Centralized Command Center

- Enhancing Efficiency Across Multiple Sites

- Tackling Challenges in Multi Location Inventory Control

- Sustainable Business Practices Through Multi Location Management

- Preparing for the Unexpected: Risk Management in Multi Location Operations

- Optimizing Your Multi Location Plan for Growth

- Summary

- Frequently Asked Questions

Mastering Multi Site Operations: What is Multi Location Management and Why It Matters

Multi-location management is critical for businesses overseeing operations across various geographic locations, requiring balanced coordination of inventory, communication, and technology to ensure operational efficiency and control.

Centralized command centers and specialized multi-location management software streamline processes, enhance security, reduce costs, and leverage AI analytics to maintain consistency and responsiveness across all sites. Effectively managing multi-location operations can lead to increased efficiency and sustainability, mitigate risks, and support strategic business growth through the use of advanced analytics, planning, and warehouse management systems.

Understanding Multi Location Management

The leap from managing one location to overseeing a network of them is not just a step—it’s a strategic vault into a world of complex dynamics. At its core, multi location management is a balancing act, requiring a deft hand to juggle the variables of fixed or temporary locations. Consider the scenario where, rather unintentionally, a business finds itself with a distributed workforce, managing multiple locations through mobile or remote employees. The criticality of effective communication and collaboration cannot be overstated; it’s the lifeline that prevents mishaps and ensures a smooth symphony across the business’s various geographic stages.

In this intricate dance of management, small scale software solutions emerge as the choreographers, supporting products and services across different locales. Picture a business expanding its manufacturing sites, driven by factors such as workforce qualifications, favorable rent, or proximity to its customers. It is within this context that the concept, challenges, and solutions of multi-location management take center stage.

Defining Multi Location Management

Consider multi-location management as the strategic command of operations across multiple facilities. It’s where the expansion purposes and autonomy level of each site are weighed with precision. At the heart of this strategy lies multi-location inventory management, which involves overseeing and syncing up inventory across different warehouses. It’s about having a multi-location inventory solution that not only integrates but also organizes operations, ensuring that location-based inventory is a well-oiled machine.

Strategic inventory allocation, then, becomes the cornerstone of operational efficiency and consistency across this network of warehouses.

The Role of Multi Location Management Software

Enter the digital maestro: multi-location management software. This technology-driven solution lifts the administrative load, allowing businesses to handle the intricacies of managing inventory, production, and multiple sites simultaneously with finesse. In a landscape where manual stock control is impractical, a digital solution becomes indispensable for multi-location inventory management.

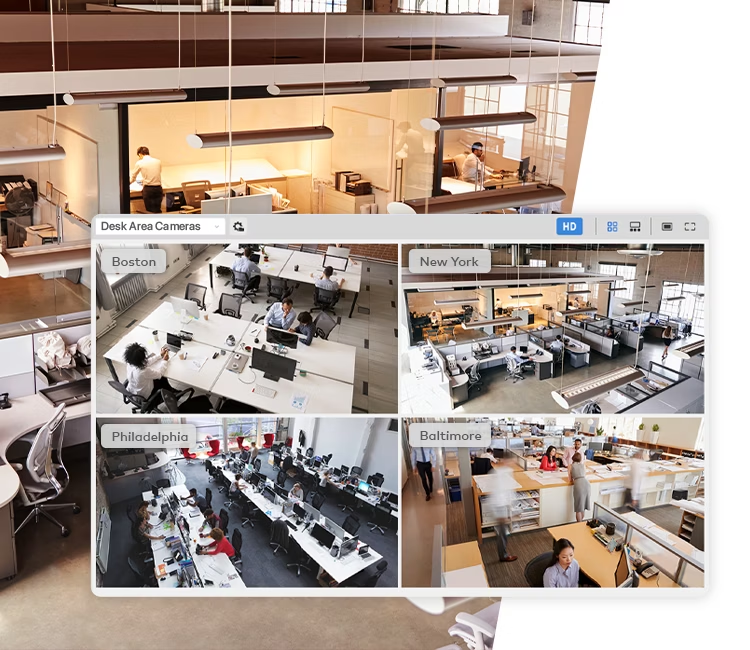

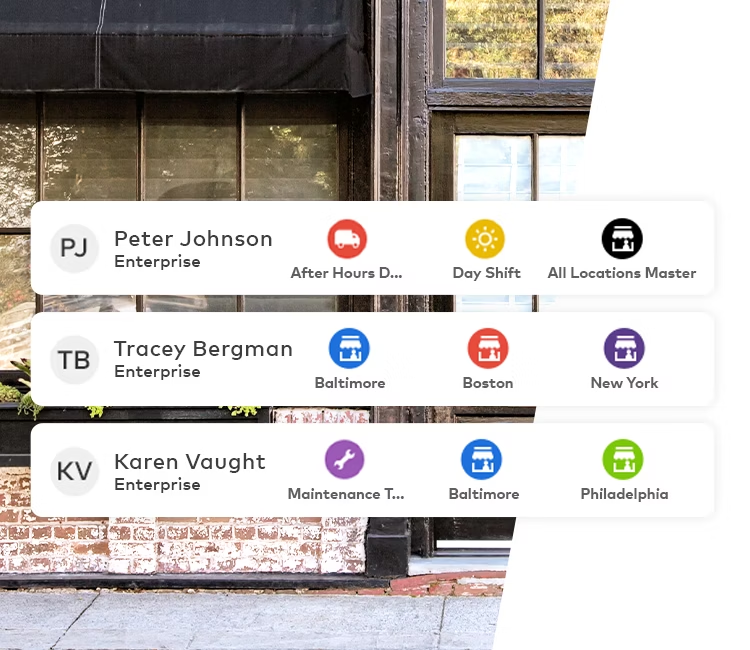

Such a multifaceted inventory management system provides a unified command of logistics, enabling businesses to tackle the challenges that come with multi-location operations. Take Securiteam, for instance, which offers advanced software to facilitate centralized control over various aspects such as access, alarms, and cameras across all locations.

The Centralized Command Center

The centralized command center is the nucleus of multi-location efficiency. It’s where decisions are not just made but are implemented swiftly and effectively, trimming down administrative and operational costs. Centralization ensures a unified vision, with consistent messaging pulsating through the company’s veins. Imagine a system that maintains visibility across the supply chain, agile enough to respond to changes in forecasts, inventory control, and cost-cutting measures.

Here, cloud technology and Voice over Internet Protocol (VoIP) become the lifeblood of the centralized command center, connecting the web of multiple sites with technological threads. This solution allows for the consolidation of all locations under a singular, powerful platform, providing unified management and control.

Access and Security at Your Fingertips

A centralized access control system offers several benefits:

- It allows management to craft global security policies from one vantage point.

- It enables efficient modification of access rights and security policies to maintain governance across every site.

- It provides convenience as authorized individuals can navigate different locations with a single access card or identifier.

Moreover, these systems are built to evolve, simplifying future upgrades to meet the ever-changing landscape of needs and risks. Securiteam’s centralized system exemplifies this by integrating control of:

- access

- thermostats

- video cameras

- security alarms

from one central location, thereby elevating security management.

Streamlining Operations with AI Analytics

Multi location managements use of AI analytics is the conductor of the operational orchestra, wielding the baton that ensures every segment of the business performs in concert. It adapts to market shifts with real-time insights, guaranteeing each location is fine-tuned for effective operation. Regular monitoring of locations through performance indicators and customer feedback is simplified, maintaining a high standard of service.

Moreover, the creation and enforcement of Standard Operating Procedures (SOPs) are supported by AI tools, ensuring uniformity in service across the board. Securiteam’s AI-powered platform offers analytics to oversee security, video, and access control systems in real time, refining the entire operational process.

Enhancing Efficiency Across Multiple Sites

The quest for operational excellence across multiple sites is relentless. Real-time data analysis through AI analytics automates tasks and sharpens decision-making, contributing to a seamless efficiency that transcends geographical boundaries. Some benefits of AI analytics in achieving operational excellence include:

- Automating tasks

- Sharpening decision-making

- Predictive maintenance, which foresees potential equipment malfunctions, thus curtailing downtime and optimizing operations.

The magic of AI doesn’t stop there; demand forecasting becomes clairvoyant in its ability to predict product demand, an imperative for strategic inventory management across locations. Machine learning models are the scouts, exploring the terrain of resource allocation and operational trends to guide enhancements in efficiency. An ongoing assessment process ensures that every location is performing at its best, underscoring the continuous pursuit of operational excellence.

Tailoring Operations to Market Dynamics

Adaptability is key in the dynamic theatre of market demand. A centralized command center amalgamates data from disparate sources, offering a panoramic view that guides informed, data-driven decisions. In sectors like hospitality, centralized systems personalize guest experiences by discerning patterns in guest data and booking behaviors, while AI’s predictive analytics anticipate customer behaviors like churn, enabling proactive retention. Cross-location collaboration tools ease the adaptation to different market dynamics, and effective communication across inventory locations helps to sidestep bottlenecks, uplifting customer satisfaction.

By leveraging demand forecasting software, businesses can:

- Ensure that the right amounts of stock are at hand, vital for operations that span international and domestic outsourcing

- Transfer underperforming products to more receptive markets

- Utilize strategically located warehouses to ensure consistent service and revenue streams.

Best Practices Deployment

The deployment of best practices is akin to sharing a secret recipe for success across a network of kitchens. Advanced analytics tools analyze performance, enabling the replication of successful strategies to enhance efficiency at multiple facilities. AI-driven insights shine a spotlight on process inefficiencies, streamlining operations, and amplifying customer satisfaction by deciphering patterns in unstructured data.

Decisions regarding complex tasks such as reservation management or stock replenishment are informed by AI’s identification of trends and patterns, setting a new standard in operational excellence.

Tackling Challenges in Multi Location Inventory Control

In the labyrinth of multi-location management, inventory control stands as one of the most formidable challenges. Communication inconsistencies, sluggish demand forecasting, and inadequate inventory management across various locations can lead to bottlenecks that slow down operations and stir customer frustration. Ineffective inventory management can strangle the efficiency of warehouse operations and production, necessitating a comprehensive multi-warehouse management system that integrates real-time tracking and control to tackle these challenges.

Proper multi-location inventory management is the wind in the sails of business growth, allowing you to manage inventory across multiple warehouses with the right tools and processes.

Coordinating Inventory Across Locations

Coordinating inventory across multiple locations is a challenging task that demands precision and foresight. The struggle for inventory accuracy and availability across all channels intensifies as businesses juggle replenishment and customer satisfaction. To avert stockouts and maintain healthy stock levels, businesses set reorder points and keep safety stock for each product in multiple warehouse locations.

As businesses scale, the addition of new warehouses requires strategies for effective tracking and management of inventory levels across both new and existing locations. Different inventories across multiple locations necessitate robust tracking to maintain awareness of each item’s whereabouts, stock availability, and replenishment needs, as enabled by solutions like Extensiv Order Manager.

Overcoming Logistics Hurdles

Overcoming logistics hurdles in multi-location operations paves the way for business growth and increased profitability. By consolidating information and streamlining processes, multi-location inventory management can:

- Reduce delivery costs by up to 25%, a significant margin for any business

- Lead to financial savings

- Result in faster delivery times

- Create more streamlined order fulfillment

Backup warehouses as part of a multi-location strategy can also contribute to these benefits.

Automation creates a network of efficiency, enabling real-time updates across all locations, which is essential for maintaining a competitive edge. By using space efficiently and storing products in smaller areas, businesses not only support sustainable operations but also reduce the need for large-scale infrastructure expansion.

Sustainable Business Practices Through Multi Location Management

Sustainability and efficiency often go hand-in-hand, especially when multi-location inventory management systems come into play. These systems optimize logistics, reducing fuel consumption associated with shipping and delivery, which in turn minimizes the environmental footprint.

Managing inventory at multiple warehouses cuts down the distances needed for product deliveries, resulting in:

- Fewer fuel emissions from transportation vehicles

- Reduced traffic congestion

- Lower transportation costs

- Faster delivery times

By implementing a multi-location inventory management system, businesses can not only improve their operational efficiency but also contribute to a more sustainable future.

Dedicated inventory management systems are a testament to the pursuit of more sustainable business practices by contributing to a decrease in carbon footprint.

Minimizing Environmental Impact

Minimizing environmental impact through strategic warehouse placement and efficient inventory management is not just good for the planet—it’s good for business. Location-based inventory management optimizes warehouse inventory levels based on client needs, streamlining the process. Placing multiple warehouses near significant customer bases not only reduces shipping and delivery costs but also boosts operational efficiency.

By implementing smarter inventory management across multiple locations, businesses can:

- Slash miles traveled by 45%, directly lowering carbon emissions from transportation

- Take a considered approach to delivery routes and inventory management

- Take a crucial step towards a greener footprint.

Leveraging Smaller Warehouses for Quicker Deliveries

The advent of micro-fulfillment centers—smaller logistics facilities strategically placed to ensure quicker deliveries—exemplifies the shift towards more sustainable logistics. Positioned close to customers, these centers make deliveries in a fraction of the time, thereby contributing to a sustainable logistics framework. By reducing the time and fuel required for deliveries, smaller warehouses situated closer to urban centers not only curtail environmental impact but can also provide significant savings on logistical and transportation costs.

With more than 75% of customers demanding same-day or express shipping options, the ability to move goods swiftly from a single warehouse to doorstep is now a significant competitive edge. These strategically placed warehouse locations enable businesses to maintain inventory closer to their customers, leading to quicker deliveries and reduced transportation charges.

Preparing for the Unexpected: Risk Management in Multi Location Operations

The unexpected is an ever-present shadow in the world of business, but with resilient supply chain management, businesses can light a torch against the darkness of disruption. Utilizing multi-location inventory management systems across different warehouses can diminish the risk associated with catastrophic events, providing a safeguard that is increasingly recognized by business leaders who are planning investments to fortify their supply chains.

Building Redundancy

Building redundancy in multi-location operations is like having lifeboats on a ship, ready to ensure the voyage continues even if the main vessel encounters trouble. Establishing backup systems and processes means operations can be swiftly shifted to alternate locations in the event of an emergency.

Possessing multiple facilities grants a company the flexibility to maintain operations uninterrupted, proving essential in scenarios of natural disasters, technological breakdowns, or other disruptions. A well-crafted redundancy strategy is an intrinsic component of robust multi-location management, protecting service continuity and ensuring unwavering customer support.

Real-Time Response Capabilities

Real-time response capabilities are the radar systems in the stormy seas of business, alerting the crew to impending dangers. Integrating AI analytics into operations assists in predictive maintenance, spotting potential issues before they escalate and scheduling timely repairs to avert disruptions.

Real-time monitoring empowers organizations to:

- Detect and mitigate risks promptly

- Keep projects on track

- Keep costs in check

- Respond swiftly to inventory fluctuations and disruptions

- Maintain a steady course even when faced with the unforeseen.

Optimizing Your Multi Location Plan for Growth

In the world of multi-location management, growth is not a finish line but a journey. To ensure this journey is fruitful, businesses must:

- Assess the performance of current outlets, pinpointing strengths and areas ripe for improvement

- Recognize those lesser-served markets with scant competition

- Seize the opportunity to establish a foothold

With a clear-eyed view of growth objectives and the resources at hand, expansion can be a calculated venture rather than a leap into the unknown. Some key considerations for successful expansion include:

- Skilled staff

- Necessary equipment

- Ample inventory

- Robust cash flow

By assessing these factors and ensuring they are in place, you can approach expansion with confidence and increase your chances of success.

Strategic Expansion Considerations

Strategic expansion is not a decision made on a whim; it involves meticulous planning and consideration of various factors. Financial independence and staffing requirements must be weighed, alongside the economic vitality and growth potential of prospective locations. Analyzing customer demand is a linchpin in the expansion process, as it leads to heightened satisfaction and, ultimately, greater profitability.

Before setting foot in new territories, compliance with legal and regulatory frameworks is paramount. Moreover, adopting Local Marketing Automation software can scale marketing efforts effectively, a crucial step when expanding a local affiliate network.

Managing Growth with Multi Warehouse Software

As businesses scale, the choice of a comprehensive multi-warehouse management system becomes a pivotal decision. Such a system acts as the cornerstone for managing growth across multiple locations, providing:

- A unified source of truth for inventory data

- The ability to manage unlimited warehouses

- Real-time data for efficient inventory tracking and warehouse stock transfers.

Without an effective multi-warehouse management system, businesses may grapple with communication challenges, insufficient oversight of inventory levels, and inaccuracies in shipping rates—all of which can stifle expansion efforts.

Summary

From navigating the complexities of multi-location management to leveraging the power of AI and centralized command centers, this guide has traversed the full spectrum of strategies for mastering operations across various sites. Embracing technology, optimizing inventory control, and focusing on sustainability are not just business strategies; they’re transformative practices that propel growth, resilience, and efficiency. As you embark on or continue your multi-location journey, remember that each location is a note in a grander symphony, and when played in concert, the potential for harmony—and success—is limitless.

Frequently Asked Questions

Multi-location management involves strategically overseeing and coordinating business operations across multiple facilities to ensure consistency and efficiency across different geographic locations.

Multi-location inventory management is important because it maintains operational efficiency, prevents stockouts, and ensures the availability of the right products at all business locations, helping businesses respond to market dynamics and manage growth effectively.

AI analytics plays a crucial role in multi-location management by aggregating data from various sources to provide insights for informed decision-making, facilitating predictive maintenance, demand forecasting, and identifying operational trends, ultimately enhancing efficiency and customer satisfaction across all locations.